Innovations in equipment and building materials have greatly refined efficiency and enabled some of the greatest feats within the industry. However, truly improving productivity in operations requires more than a sophisticated scraper, bulldozer or drill.

Technological innovations on a smaller scale, from laptops to GPS, often have the greatest impact. The challenge for construction firms, small and large, is introducing a culture of technology to people who, for many reasons, do not embrace the need or desire to utilize it. The construction industry as a whole remains a late entrant into the technology race, encumbered by complex problems and poorly equipped users.

Software firms abound with solutions to construction’s ever-increasing list of demands. Document control, scheduling, collections and even grade control are on the short list of management functions reduced to mere keystrokes with the purpose of improving productivity and efficiency. Capitalizing on these advancements not only serves as a market differentiator but also enables increased efficiency at many levels within the organization.

The main challenge lies in the human element. “I don’t know even know where the on button is,” is a common response from many field managers who have dedicated their life to moving dirt or installing drywall, but have little regard for the laptop computer. Even with the most experienced user, the technology is diminished when it serves as a reactive mechanism to problems or challenges.

The long term solution involves creating a culture of proactive communication and planning. Best of class contractors gain the maximum efficiency from their teams through a comprehensive and detailed strategy, no different than introducing a new safety or quality control program. These same contractors understand the value of training and find ways to integrate these new systems with maximum efficiency.

A Strategic Perspective

Technology decisions are no different than fleet decisions or tool crib decisions. Purchasing tools and equipment requires judicious care to ensure they meet the need, in both form and function. One does not buy a rotary drill when a circular saw will do. Furthermore, expensive fleet purchases require even more care to ensure effective and productive utilization over a long useful life. With information technology purchases, owners must determine what will successfully integrate and link their legacy systems while creating a new platform to deal with current and future challenges. Can a new system mirror the old way while providing the right level of innovation for operations in the future?

Consequently, contractors labor over the biggest and best systems, hoping to find a fully integrated solution to suit their needs. Often, the cobbled together systems that support operations don’t function seamlessly—scheduling by Brand X, cost control by Brand Y and document control via a complex series of spreadsheets and databases. In many cases, the technology available to contractors vastly surpasses many of their needs.

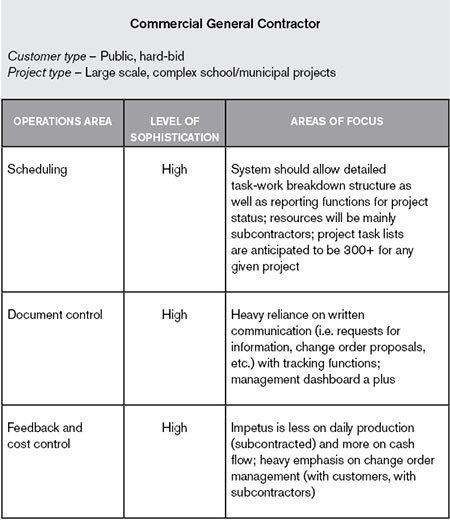

The first question that needs to be answered lies within the strategy of the organization. What does the vision of the organization say about the size, complexity, delivery methodology, etc. of the projects they are to manage? The tools needed to support operations will vastly differ if the firm is dedicated to mass earthwork projects rather than multistory condominium projects. While the software and platforms may be similar, the utilization of the tools will not. There is no one-size-fits-all perspective.

Use a focus group of managers and superintendents to determine system requirements. Work to understand their needs and discover what will improve planning, communication and efficiency. (Fig. 1) Buy-in to the system begins here. Without agreement, managers and superintendents gravitate towards their own ad-hoc systems.

Furthermore, as operations personnel rely on their own systems, critical data and project information becomes fragmented and inconsistent. Additionally, important project metrics such as change-order approvals, schedule performance and aging receivables lack integrity and credibility. Examine the problem and challenge from the users perspective to gain a better understanding of how to maximize the system’s implementation.

Focus on the Champions

Even with the needs clearly identified, implementation requires patience and careful selection. Many firms have faltered at this stage because of senior management’s failure to effectively roll out the system and demonstrate its benefits to the team. The buy-it-and-they-will-use-it strategy only caters to a small percentage of early adopters who need little motivation to use new technology. However, these individuals will help endorse and sell the system to the rest of the organization.

It is imperative to identify the right team with which to begin implementation. The pilot group enables the firm to examine the most efficient methodology moving forward and helps create continuity as new projects adopt these new systems. Debugging the system continues long after the software leaves the factory. Customizing reports and project infrastructure at the project level early creates a stable foundation for future projects. More importantly, this provides a “grown here” feel rather than that of the generic quick fix.

The momentum generated by this group of champions helps sell the next group as well as dissuade dissention from would-be system saboteurs. While information technology is largely a hard science, the success relies in the psychology of thwarting those that would derail the implementation. Reasons for non-acceptance range from lack of training to simply a general ignorance of a system’s benefits. By extolling a system’s virtues and celebrating the successes, people riding the fence of acceptance face easier decisions.

Mentoring and Training

The next challenge is dealing with the would-be assassin, naysayer and neophyte. Companies routinely spend countless dollars on basic computer training. These courses offer a fundamental knowledge of how to turn on the computer and get on the Internet. Long after the course ends many questions still linger, and the laptop sits in the trailer or on the passenger seat of the truck, unused and underutilized. The loss associated with the cost of a wasted computer pales in comparison to the losses in productivity, whether as part of the job-cost feedback system or simply the result of a communication bottleneck.

On another front, as companies deal with these technological issues their organizations get older. Across the country, companies struggle to meet the industry demands because of a lack of skilled labor brought about by the aging workforce. A great divide exists, as younger project managers and engineers are paired with older field managers and superintendents who possess significantly different perspectives and skill sets to complete complicated projects. How does an organization create synergy and a productive environment with a team that sees the project from different perspectives? Senior management must determine how to bridge the gap created by attitudes toward technology.

Mentoring is one strategy to create a proactive training environment that allows both groups to benefit. As older members of the team retire, companies lose a knowledgeable asset. Capturing that knowledge is paramount. Furthermore, another source of pain in many organizations stems from younger managers and engineers who lack the necessary practical knowledge to make educated and informed decisions about projects. Great companies have found a way to insert new associates directly to the field where they learn critical constructability lessons from the field manager. It is here that a symbiotic relationship can exist.

Pairing the right individuals together and carefully explaining the benefits of such a pairing should be an early step in the process.

Thrusting a young engineer or assistant onto the site of a lone-wolf curmudgeon with no explanation will only frustrate both parties and provide little educational opportunity.

A structured process and proactive communication helps create a strong system of future producers and the opportunity to truly teach the old dogs some new tricks.

Overreliance on Technology

Cellphones now receive email, voice mail and television. The capabilities of some scheduling software surpass the needs of many contractors simply trying to create a bar chart.

Technology offers many opportunities, but without strong fundamentals it will never be the panacea that construction firms desire.

For example, wallpapering trailers with grandiose Gantt charts are no substitute for good quality planning. A schedule is a piece of paper. Planning requires thought and interaction.

Ask a project manager or superintendent about their plan and without fail, you will be handed a bar chart. Efficiency and productivity increase not because of the bandwidth or an Internet connection or number of tasks on a Gantt chart, but rather because teams have engaged in the appropriate level of planning before, during and after a project.

Voluminous cost reports teeming with columns of data never serve their role if they are neither shared with nor understood by the intended audience. Green bar sheets often litter the landscape of a trailer, leaving critical production information unread.

Knowing the score provides critical information to the field about their performance. Management must ensure the distributed information speaks to its audience. Provide meaningful graphical feedback on performance. Sharing this information with the crew involves the team in the project goals as well as drives the right behavior.

The construction industry relies heavily on the human element but the integration of man and machine in construction is slowly becoming a competitive advantage for some firms.

Those that have found a way to distinguish themselves from the competition by incorporating a technology-now strategy with an effective implementation plan can not only eliminate the competition but also enhance operations

through efficiency.

Technology, from GPS to laptops, need not be limited to tech-savvy managers and superintendents. Nor does technology only have to serve the large organizations. Implementation and successful training of a single strategically viable tool connected with a fundamental business process creates the brawn that will create the engineering marvels of tomorrow.