Checklists, testing and manuals — if the topic of quality control is brought up at any construction company, those are usually the top mentions, and they are often followed by a deep yawn. Quality control is certainly an essential part of any organization’s infrastructure. However, when looking closely at methods of ensuring a quality product and/or service is offered, especially in an industry characterized by low margins and high risks, a question arises: Is leaving potential rework conditions until the end of a specific phase — or the project as a whole — a reactive and ineffective situation?

To answer this question, it is important to examine the true cost of rework. While hardly an exact science, Figure 1 gives a brief summary of the potential cost multipliers that come with rework.

One must assume the initial cost of putting the work in place, but when one considers that rework could have a cost multiplier of 10, quality control seems somewhat defensive in posture. In the end, with every mistake there is a potential impact to more than the bottom line, as is demonstrated by everything from employee morale to customer sentiment. So, how does a firm create a culture of quality assurance to complement their quality control?

Migrating From Checklists to Collaborative Tools

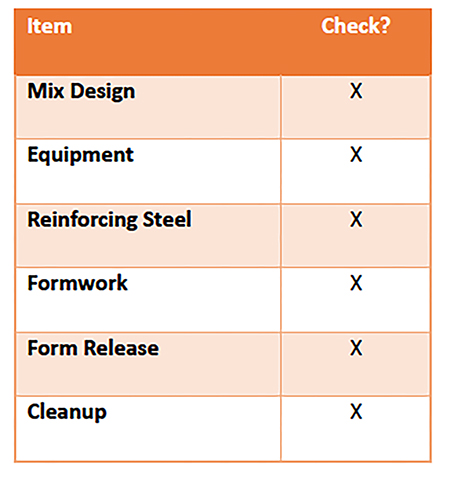

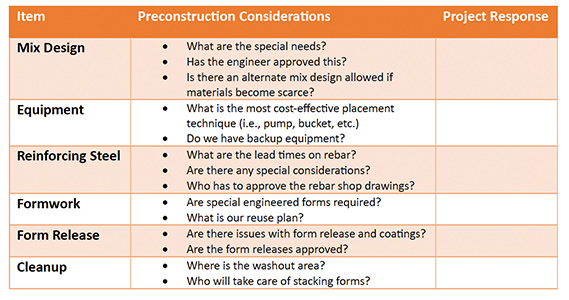

Checklists serve a function. However, they tend to be incredibly superficial, and with so many industry professionals who lack experience, there is a risk of simply “pencil whipping” the checklist. Consider the comparison in Figure 2.

A more experienced manager or field leader has probably considered all the alternatives with Option 1. Option 2 asks questions that force the team to think through the options. For instance, consider the question of the compatibility of the form release and any painting or coating. There are plenty of instances when someone might not have asked this question early enough, only to find out too late in the process that entire wall systems needed to be power-washed for fear of a paint not adhering to the substrate.

Option 1

Option 2

Red Teaming

Bryce G. Hoffman, the author of “Red Teaming,” created a masterful concept for all businesses that builds upon the thesis the military uses in its exercises: In any war game or simulation, there is always a team that plays the role of the enemy insurgent. Even in sports, the scout team will run the opponents’ plays and simulate an environment reminiscent of what the first team will see on game day. Organizations can use a similar technique in several capacities to drive a quality assurance initiative. For instance, consider the following processes:

Red Teaming After Preconstruction

Once the team that will build the project has developed an effective plan, a “red team” is organized to challenge the assumptions. These challenges might sound like:

- How will you protect the finished product from damage from other trades?

- How will you manage to drive 1% to 2% more profit to the bottom line?

- How will you avoid a voluminous punch list?

- How will you integrate the service department sooner?

The intention is to create a stimulating yet uncomfortable set of questions to ensure the project team can effectively execute the work. An answer like, “We’ll just do our best to protect the project from damage,” should be a red flag, as no real precautionary planning lies behind it.

Red Teaming During Construction

Next, bring in a small team to simulate a surgical strike at a random time on the project. The intention is to prepare the team before closeout. Too often, issues are left unsettled until the end, leading to the aforementioned punch lists and, ultimately, annoyed customers. The red team’s main areas of focus are:

- Project cleanliness

- As-built drawing and closeout documentation

- “Next-step” preparation (Does the team have the next three to four moves well calculated?)

Red Teaming During Closeout

To be clear, this method does not employ a separate punch list crew or team, but rather another project team enlisted to be that extra set of eyes. How often does a project team wear that set of rose-colored glasses? The red team attacks every aspect of the project from punch list to closeout documents. Certainly, this could be perceived as rework, as any punch list would be, but it is important to note that this puts the red team in the shoes of the customer prior to the actual customer closeout. It prevents repairing customer perceptions and ultimately truncating the closeout timeline.

Valuing quality assurance over quality control is by no means a new concept, and there are professionals who focus solely on ensuring companies provide both quality assurance and quality control. However, there are also organizations that see dedicated professionals as a luxury or added cost.

The intention of quality assurance through red teaming is to provide proactive solutions with the project teams. Even the red teams are simply redeployed team members who could easily be on the other side, playing defense. Firms that integrate assurance into every aspect of their work create the ultimate assurance in the end: profitability.