How your business handles its back-office processes, and the timing of those processes, can greatly impact decision-making and affect your bottom line. If you were flying a plane and your GPS only showed you where you were once an hour, you could end up in the wrong place. Unfortunately, these processes are often performed manually and are prone inefficiencies, like sorting through boxes of tickets and invoices. In fact, it’s estimated that up to 40 touches are typically needed to successfully execute an order-to-payment process and keep track of costs. Automating these processes can impact profitability, cash-flow and positively affect the entire organization.

The monumental task of getting all invoice data coded accurately into the accounting system is a huge undertaking. Manually entering data requires a lot of time that could be spent focused on other aspects of the business that need attention.

The wage of a construction worker is rising due to inflation and aging out of the workforce. The Infrastructure Investment and Jobs Act will provide a historic increase in construction industry spending. That means that there is more demand for construction workers than ever before, and at a time when the average worker has more choices for jobs outside of the industry. The increased need for workers, combined with the competition of other industries and inflation means that labor costs are rising significantly. The need to maximize the value of staff and reduce their time spent on nonproductive tasks is paramount to success. These non-productive tasks also leave you susceptible to errors. Oftentimes, these errors go unnoticed until month-end close, creating extravagant costs that are easily avoidable.

Labor, equipment and raw materials are big chunks of costs. Equipment also needs fuel, and the rising cost of fuel increases the need to track costs on a line-item basis, perfectly and in real-time. Unfortunately, it takes a lot of work to pay invoices and track costs — buyers must receive, validate, approve, send and ensure that payment is received by their supplier, usually in 10 days or less. This is no easy feat for most companies to do on a regular basis.

Too Late? Too Bad

For accurate cost management, accounting teams must record each line item from an invoice and what cost item it belongs to. The benefit of differentiating all these costs on the front end by cost-coding is that it gives visibility into whether they are tracking behind or ahead what was estimated.

For most projects, the two biggest goals are completing the project on time and on or under budget. The construction industry fundamentally operates with low, single digits of margin. That means that if the project is slightly off in estimates, the project owner could end up completing a massive, multimillion-dollar project that took several years to fulfill with little return.

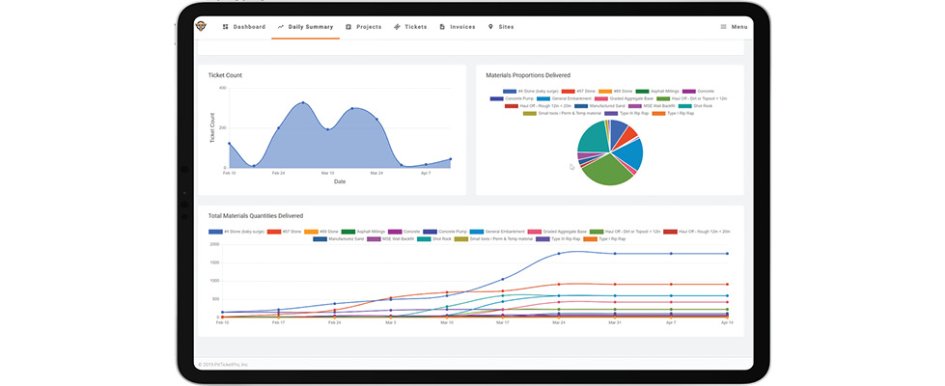

A way to combat this and drive profitability is to measure forecasted cost against the actuals in a timely manner. With traditional processes in place, the project manager might not have this visibility for a month if they are purely relying on an accounting system. This pace is an issue because if something is out of skew, there is not much time to adjust. These are insights that are needed daily, or once a week — not once a month.

The Power to Track Your Major Project Costs

Over 90% of leading contractors add financial management systems to their accounting systems that give them the real-time visibility that the accounting system is not typically designed to handle. Automation can speed up the most time-consuming processes so that the organization does not suffer from the time costs and errors associated with getting all the invoice data coded.

Employees are not saddled with the task of keying in all the data, freeing up time for more impactful work. Instead, the data is automatically captured and fed into the accounting system, drastically cutting back the number of errors that hold teams up in their month-end close.

These financial management systems can provide information about how your costs are trending on a real-time, daily or weekly basis. These financial management systems have proven to be successful, but there are a few gaps in some of these systems — they do not provide an integrated view into certain subcategories of costs like trucking and materials. However, solutions exist that can be integrated with these systems to enable back-office personnel to capture every single material and transportation ticket that hits a jobsite.

For projects that do not have standard e-ticketing operations in place, optical character recognition (OCR) and artificial intelligence (AI) technology makes it possible to capture 100% of material and haul tickets as early as possible, re-digitize them and then utilize the digital data for job cost reporting, accruals reporting, invoice reconciliation, quantities delivered for project managers and insights for improving job efficiency. OCR technology extracts data from paper tickets via a mobile device in the field or office, through scanner integration, directly from the scale printer or as soon as they are created by the scale operator.

All the tickets and invoices live in one place while AI technology automatically matches up every line item, flagging the user if they are being overbilled or highlighting other exceptions requiring clarification. Once the payment is authorized, the invoice makes its way to the person who will execute the payment. By automating the execution of payments, approved payments can be scheduled and sent automatically and stored in one central location, making it easier to pay electronically and cut costs and risks that come with every payment.

Immediate Access & Visibility to the Right Data

Longstanding practices in heavy materials management have proven tedious and error-prone, requiring numerous phone calls, emails and handling hundreds of thousands of multi-part printed tickets across trading partners. It’s time for project owners to say goodbye to passing five-part printed forms back and forth to get the heavy job done.