In the ever-evolving world of instantly available information, contractors must be able to determine which information is accurate and usable on the jobsite. Even when the information is provided via printed plans and documents, it is often transferred to a digital form or via models created using building information modeling (BIM) applications. This transfer of intelligent information is a critical point in the construction process and is vital to a project’s overall success.

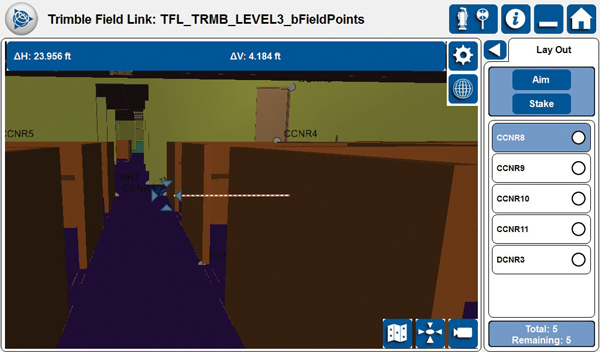

A model being used to intelligently collect or position data in the field. A robotic total station positions the operator in the 3-D model and navigates the individual through the model to the specific point for layout or QA/QC.

A model being used to intelligently collect or position data in the field. A robotic total station positions the operator in the 3-D model and navigates the individual through the model to the specific point for layout or QA/QC.Mobility of Data

Until recently, project teams have often been reliant on individuals to supply end-of-the-day updates that may not have been recorded accurately and that contain little intelligent detail of what had been constructed or positioned that day. While teams still managed to complete their projects, the information lag led to inefficiencies, loss of productivity, increased project cost and missed schedules.

A good example of this information lag can be found in the errors associated with tape or string measurements. Most workers on a jobsite know how to use a tape measure, string line, plumb bob or level. However, many people don’t realize that tape measures can actually produce false measurements. These inaccuracies can be the result of many factors, including deflections over uneven surfaces such as dirt or materials, temperature variations causing the steel tape to shrink or stretch, or the pressure applied when pulling on 100- or 300-foot measuring tapes. In addition, when using grid lines or other references for a measurement, a worker could easily be off by a half inch every 20 feet if not pulling at an exact 90 degrees or if he or she incorrectly positioned the 3-4-5 triangle. Other issues can arise from simply misreading the tape measure or inaccurate addition or subtraction of dimensions from the drawings—especially in the U.S., where calculations include numerous fractions of an inch.

More important for today’s highly litigious construction market or for more sophisticated BIM projects, a tape measure cannot provide a record of measurement. Did the worker use the correct dimension? Was the person on the other end of the tape measure burning 1 inch or 1 foot to get a more accurate measurement? Was the end of the tape measure worn out from use? From which version of the drawings or model was the measurement derived?

Today’s business environment expects that projects will be managed with greater efficiency in cost and schedule control than ever before. To ensure this success, information mobility and the ability to update information in real time has become a mission-critical workflow component. Data mobility allows information to be disseminated and used by a multitude of devices, whether for project management, scheduling trades, updating task completion, coordinating materials or accurate position (site layout).

Intelligent Information

Key to data mobility is the sharing of that information, making it essential that the collected information be populated with as much intelligent data as possible. Intelligent information ensures that key stakeholders located either at the construction site or in the office have usable data to make informed decisions. Without intelligent information, analysis of the data becomes cumbersome, difficult to interpret and less valuable to the project stakeholders who need it for key decision-making processes.

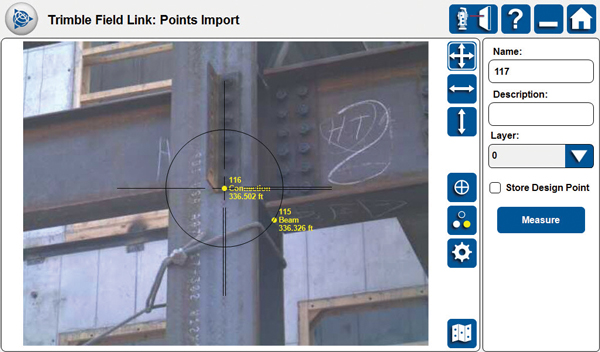

For example, when a field crew is either laying out data in the field or doing a QA/QC as-built, they can position information and populate the data with additional intelligent information, such as time of capture, length of time to complete the task, description of the element being captured, state of construction progress, along with traditional coordinate position, which includes any variation from design intent. Some of today’s robotic total stations have vision technology included, allowing images to be added to the data collected.

All this adds up to what has become known as intelligent positioning. An example is shown in Image 1, with information being positioned and collected in the field. Coordinate data, descriptive data and model layer data are all being used and collected.

Image 1. Live camera feed from the robotic total station assists in positioning objects, captures an image and adds the image to the database as an additional layer of intelligent data.

Image 1. Live camera feed from the robotic total station assists in positioning objects, captures an image and adds the image to the database as an additional layer of intelligent data.Field Implementation of BIM Intent and Intelligent Positioning

With the ever-increasing use of BIM on jobsites, taking this information into the field is becoming a key component of successfully managing a project. These building information models can be used in the field to position and collect valuable data that can be shared and be made transparent for all the appropriate stakeholders of the project. This intelligent data can then be used for scheduling, cost estimation, design updates and safety analysis.

As the use of BIM grows, contractors, superintendents and project managers must be able to manage and populate the construction model to ensure that data integrity is maintained. In this way, the model will be constantly updated with intelligent information from the field and the office so that key decisions can be made with the most accurate information available.

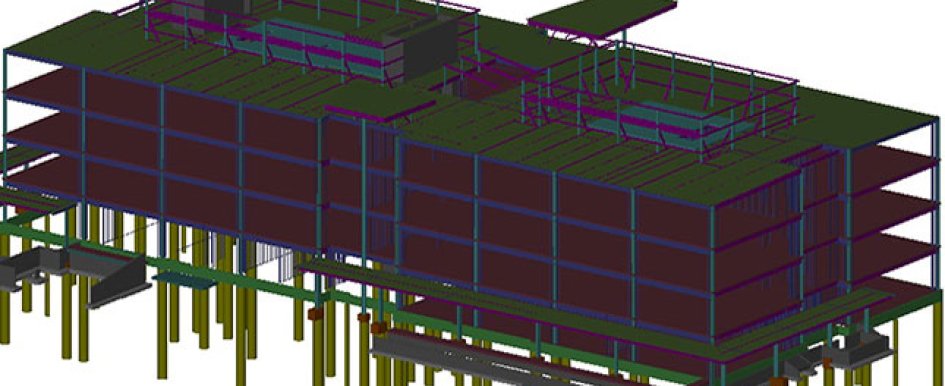

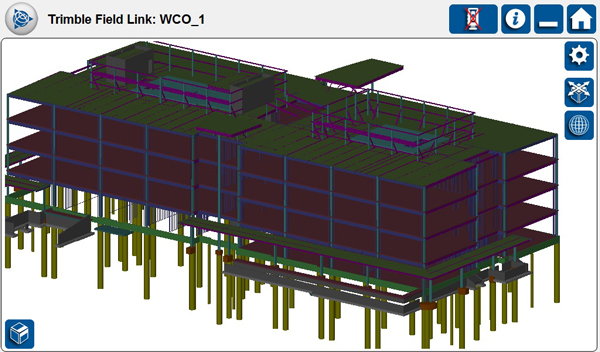

Image 2. Sophisticated 3-D BIM model being managed in Trimble Field Link software. The model is used to manage day-to-day layout and data collection activities.

Image 2. Sophisticated 3-D BIM model being managed in Trimble Field Link software. The model is used to manage day-to-day layout and data collection activities.A site engineer can use a model to create detailed layout data of key objects to be positioned and constructed. As an object is positioned, each element can be populated with critical data that can immediately be transferred from the field data collector’s tablet computer directly to the construction site and the coordinating office locations. The data then can be used to update the BIM model in near real time. Image 2 is an example of model data in use for positioning in the field.

Continuity of Process

With the implementation of BIM as well as mobile project management of data, workers must become more aware of maintaining the consistent flow of data between the office and the field. With the continual flow of intelligent data, project teams can maintain a consistent level of continuity of processes, which leads to a greater level of analysis and critical decision-making to maintain high-level project performance. With intelligent positioning, it’s now easier to maintain the original design intent and capture and share critical data during the project.