With augmented and virtual reality, drones and a host of other tech solutions becoming synonymous with the modern construction landscape, it’s easy to feel overwhelmed with options. 3-D printing has been a buzzword in the industry for a while now, but a new use for the technology is taking the architecture, engineering and construction AEC industries by storm: 3-D printed project models.

With a foothold in web content and media, WhiteClouds CEO Jerry Ropelato branched the company into the 3-D printing world a little over 4 years ago. The company initially started with three consumer 3-D printers and a commercial printer. At that time, people organically started coming to WhiteClouds for 3-D printing.

“Consumer printers were starting to take off at that time, but a lot of companies didn’t know how [3-D printing] was going to change their business,” said Cris Flowers, marketing and business development for WhiteClouds. The team at WhiteClouds realized there was a good opportunity for printing in the architecture world, and started going after customers in the industry. “At the time, we really had to educate the market about how the models that were built by hand could be 3-D printed for less money and with more detail,” Flowers said.

Since then, WhiteClouds has seen great success in the AEC industries, now printing both commercial and residential models. WhiteClouds currently works in the industries of architecture, medical, entertainment, rapid prototyping and induced parts. According to Flowers, approximately 60 percent of the business is commercial buildings and 40 percent is residential. In the commercial bracket, the company also produces developments, and plans to stay on this growth strategy, with the exception of one additional goal: to make the models more affordable for smaller businesses.

“We are doing more models for bid openings, which need to be as affordable as possible. The models show where cranes will sit, and where the supply inventories and site openings will be located during the construction process,” Flowers said.

That kind of overview of a construction site is invaluable to the entire project team, no matter the project type. In one Utah construction project, the benefits of being able to see a mockup of the finished project helped in myriad ways.

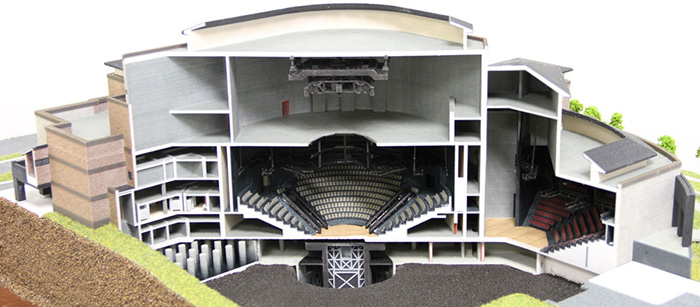

WhiteClouds recently completed a 3-D printed model of the new Hale Centre Theatre in West Valley City, Utah. Prior to the project’s start, the model was used to invite donations from theatre donors. The Hale Centre relies heavily on donors to fund all of its projects, and the model allowed the project owners to say, “This is what we’re building; come and be a part of it,” Flowers said. The project is set for completion at the end of 2017.

The process that goes into designing and printing the model can be fairly complicated, depending on the detail required. First, WhiteClouds receives the file from the architect or construction company requesting the model. There is often a disconnect between the construction and architecture software systems and the 3-D printer, so an in-house team takes the files and converts them to a 3-D printable model. The Hale Centre Theatre was a complicated building, which included a stage, overhead scaffolding, landscaping files and more.

After creating the initial file, the team sends it to be printed. The theatre was printed in several pieces due to the structure of the plans. The material used for the main structure of the building was a sandstone powder. Because the stage and scaffolding were so small, the team used a UV-cured resin, which is a plastic once cured. This material allows the team to print in minute detail. The conversion process for the files took about 40 hours for the Hale Centre Theatre model, according to Flowers. The total print time on the model was around 70 hours, with multiple printers running at once. The process length can vary depending on the project.

The cost to print a model similar to the Hale Centre Theatre is approximately $25,000, depending on the amount of detail required. And detail was the name of the game for this particular project. The landscaping on the model was printed using high-density foam and a CNC machine. The team creates the file in 3-D, and then the machine goes in and carves out the high-density foam to match the topography of the building. The team also used traditional hand modeling for the plants and grass. Some of the landscaping was 3-D printed, though, such as the rocks and water features. The team added fiber-optic lighting and LEDs to display how the stage lighting would cast shadows and light the auditorium. The stage lighting allowed donors and architects to see exactly what the finished product would look like prior to construction.

One of the best use cases for the model involved planning for a large water table in the area where the theatre will be located. The architects had to build pylons into the ground to anchor the model. The water table would push the building up and out of the ground like a boat, so the architects built these pylons to anchor the building in the earth, Flowers said.

Thus, one of the most obvious benefits of a model like the Hale Centre Theatre product is that it puts everyone on a project on the same page. “We live in a 3-D world. Unless you are an architect of a builder, it’s hard to visualize what a building is going to look like,” Flowers said. “When you have a 3-D model, it tells the whole story. A rendering doesn’t exactly give you the same perspective, and having a physical model really improves the communication involved with everyone in the project.” The model creates a discussion between the architect and builder, so they can look at project details, such as rooflines or floor layouts, and come to solutions together.

For Hale Centre Theatre’s Director of Development, Quinn Dietlein, the model continues to provide for the theatre, even after the initial fundraising for the project. “Last year, we had 286,000 patrons come through the theatre,” Dietlein said. “Not only does the model help raise funds, but it has also helped patrons feel more confident in purchasing tickets in the new theatre because they can see the model.”

While the Hale Centre Theatre project is not one of the biggest projects financially or in terms of size for WhiteClouds, Flowers said it is one of the most intricate models the team has ever done.

As for the future, WhiteClouds expects to complete more models with interactive features and tech integrations, which might include LED lighting, a jobsite crane that moves back and forth to show the area the crane would take up, iPad integration, voice-narration to describe different features of the project and more. The company recently implemented its first model with augmented reality.

Whether commercial or residential, large or small, one thing is true for any construction project: costly rework results in profit loss for companies of all sizes and specialties. 3-D printed models could be the solution to alleviate this issue.