As a business owner, unexpected maintenance can place financial strain on your company and directly impacts profitability. To make matters worse, you or your equipment operators may not have adequate service training or access to an on-site mechanic for the repairs that get your compact equipment up and running. That’s why partnering with your local equipment dealership for parts and maintenance can be beneficial. Dealerships have the time, tools, knowledge and parts availability that give you the best chance of maintaining a healthy compact equipment fleet.

Dealership Expertise

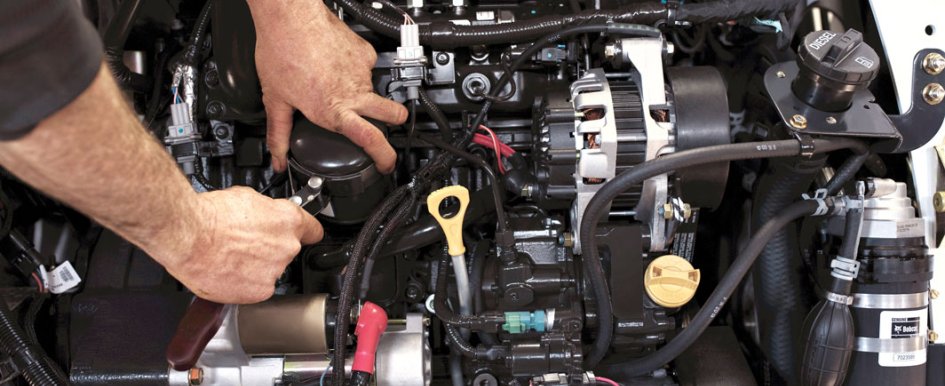

One of the biggest advantages of partnering with your compact equipment dealership is having trained technicians with access to the latest information, resources and tools concerning your equipment. They know what to look for, and they have the proper training on the latest emission standards, how to calibrate the machines and how to check diagnostics with tools and software that are typically not available to customers. In addition, your dealership’s service team should know what parts are stocked, and can help ensure that your scheduled maintenance is performed according to the recommended service schedule. You may consider creating a planned maintenance contract to ensure you are following the recommended service schedule. A planned maintenance contract can better assess what equipment and tools are needed to keep your compact equipment running properly.

Fluids & Filters

Dealerships stock engine oils, coolant, hydraulic fluid, grease and drive-motor lubricants to help you follow your service schedule and minimize downtime during your busy months. They can help match excavator and loader fluids to the proper ambient temperatures and to the manufacturer’s recommendations. Your dealership can determine if you need synthetic or synthetic-blended oils, which are formulated with additives that can extend oil change intervals and promote longer engine life. These oils have better cold weather starting and lubricating performance, as well as additional wear protection during high-performance operation.

Fuel and air filters should also be changed according to your machine’s recommended service schedule. Dirtier and dustier conditions may require filters to be changed more frequently. Regular inspections, as outlined in your equipment’s operation and maintenance manual, will help your dealership identify when to change filters.

Speak to your dealership about purchasing fluid and oil analysis programs. Each program provides reports and insights that can help you better understand the current operating status of your machine. With the oil analysis program, you can examine what is happening inside the engine, gearbox or hydraulic system without disassembly. The practice of regularly sampling and monitoring test data can expose trends over an extended period.

Tires & Tracks

You rely on tires and tracks to give you long-lasting performance when paired with compact equipment. You also rely on your dealership to have the proper replacement parts in stock in case you encounter a flat tire or if a track is loose. Make sure your dealership knows the scope of work your business is completing so they can have the proper replacement items in stock. For instance, if you are excavating, grading or performing other construction tasks, consider a pneumatic tire for superior traction. However, if you are working in demolition situations, a solid tire will resist cutting and chunking caused by debris.

The life of a pneumatic or solid tire depends on a variety of factors, including the application where it is used. You may get 1,000 to 1,200 hours of use on one set of tires when working on sand or very soft ground. However, if you are working on hard dirt, gravel or rock, you should expect between 600 and 800 hours of life. When working in severe operating conditions on only roads and parking lots, you may get 400 or less hours of life from tires.

If you own a compact excavator or compact track loader, your dealership should have a variety of wide or narrow tracks to match ground conditions and different tread patterns on the tracks to suit your individual needs. Wide tracks work well when lower ground pressure and flotation are desired, while narrow tracks add increased ground pressure, traction and pushing force. The tracked undercarriage provides lower ground pressure, improved flotation and traction, helping distribute the machine’s weight across a larger area. The undercarriage consists of many moving components that need to be inspected frequently, especially if the machine is being used in harsh applications or challenging operating conditions.

Genuine Parts

It can be tempting to cut costs with lower-priced alternatives, but with today’s emission regulations and sophisticated treatment systems, cheaper options could cost you more in lost time and revenue than using genuine original equipment manufacturer (OEM) parts. Dealerships stock OEM parts, and often carry a warranty that can help protect the overall value of your machine. Using genuine parts helps extend the life of your machine, but will also give you the peace of mind that your equipment will continue to function properly.

Opportunity Costs

You should evaluate the savings gained with having a dealership service your compact equipment. Opportunity costs can vary based on rates and accurate time estimates, but in many cases, your dealership can perform many routine maintenance tasks in significantly less time. Utilizing a dealership is not only appealing because it can be the cheapest option, but also because it can be the most convenient and reduce downtime.

Poor equipment performance and component failure can be frustrating, but consider visiting your local dealership to perform service on your compact equipment. They have adequate service training, access to the right parts and have on-site mechanics available to get your compact equipment operational. Proper and timely scheduled maintenance can help extend the life of the equipment, minimize downtime and save you money over time.

Compact track loaders can be equipped with a variety of rubber tracks.

Custom, C-pattern rubber tracks provide the best combination between flotation and traction, but there are a variety of tread patterns that can accommodate various applications, including:

- Multi-bar lug—Offers a smoother ride than traditional lug patterns and has excellent traction with a greater number of tread lugs per foot

- Multi-bar lug (non-marking)–Provides an option for sensitive worksites

- Non-marking—Designed for turf and landscaping applications where reduced ground pressure is desired