Despite ongoing efforts by construction firms and law enforcement, the number of heavy equipment theft reports in the United States continues to grow. In 2016, more than 11,574 pieces of heavy equipment were reported as stolen through the FBI’s National Crime Information Center (NCIC).

Equipment theft occurs in every state, but the states that reported the highest equipment theft were Texas, North Carolina, Florida, California and Georgia. Together, these five states accounted for 45 percent of total reported equipment theft.

As a heavy equipment owner, there are several steps you and your operators can take to reduce construction equipment theft from your jobsites. Of course, no jobsite is exempt from the risk, but these tips can help you keep your jobsite and your valuable construction equipment protected from theft and vandalism.

1. Maintain a Secure Site

When beginning a new project, your first line of defense against equipment theft is jobsite awareness. For instance, if you are leaving your heavy equipment overnight on the jobsite, make sure the area is well-lit and easily seen from a road to deter thieves. In addition, set up site security devices, such as an alarm system or video surveillance to monitor the site during working and nonworking hours. Some common-sense tips that should not be overlooked are locking the cabin door and closing any windows when the operator is done working. Do not leave the keys with the machine. Other proactive steps you can take to secure the jobsite include:

- Get to know other companies or contractors working on the jobsite

- Add a chain-link fence or gate

- Post warning and no trespassing signs

- Limit the number of individuals with access

- Install security lighting, or use a light tower to illuminate the jobsite

- Consider hiring a security guard service for larger jobsites that contain high-value equipment

If you are unable to secure the jobsite, or you are concerned about the security of your equipment, look for a safer area to store your equipment within driving or hauling distance to your jobsite. It may be more work upfront, but it can be worth the costs when it comes to preventing theft.

2. Know Your Equipment

It sounds simple. How well do you really know the equipment on every project? Familiarizing yourself with the make, model number, serial number and purchase dates of heavy equipment and keeping that information on file is another way to help reduce the chance of theft. Take a picture of every machine, and save it with the machine details. This information should be stored in a secure location, away from the jobsite. Ask your equipment sales specialist if you are unaware of the serial plate locations on your machines.

In addition, make sure to register your heavy equipment through the National Equipment Register (NER) or the NCIC to help increase your odds of recovery if the equipment is stolen. The NER is a national database of stolen heavy equipment and ownership to help recover equipment for owners and insurers of equipment.

3. Utilize Fleet Tracking Technologies

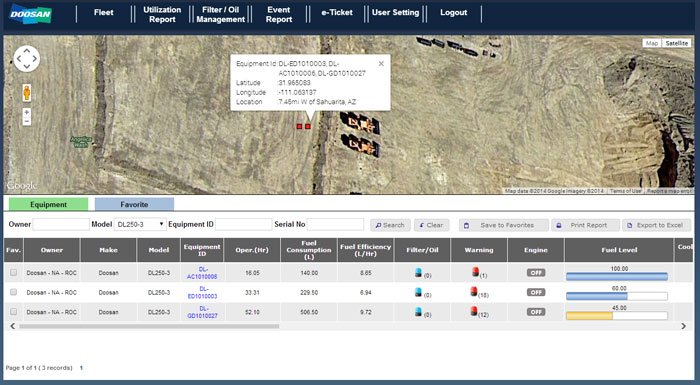

As an added means of protection, today’s heavy equipment is likely already equipped with on-board, fleet-tracking technologies to track and report data in real time. Telematics systems can provide you with a better understanding of how, when and where construction equipment is being used. The location is provided in longitude and latitude, and the mapping software automatically changes to the closest address.

In addition to tracking the physical machine location, many equipment manufacturers offer a geofence or time-fencing feature to help business owners or fleet managers monitor unscheduled use and track machines in the event of theft or vandalism. With a geofence, you can set virtual GPS boundaries, and if a machine moves outside of the boundary, you are notified via email or text message.

Many fleet-tracking technologies use a terminal that is installed on the machine to gather and communicate data wirelessly via cellular or satellite service. The machine’s data is then sent to a website, where you, your operators and your equipment dealer can monitor the machine’s performance, operating hours, fuel usage, engine idle time and work time. You can also monitor engine/hydraulic oil temperature and monitor fault and warning codes via a computer or cellular device.

4. Train Operators on Site Protocol

On any construction jobsite, it is important to educate your equipment operators on site protocol. At the end of each shift, have your operators park the equipment, shut and lock the cab door and log each piece of equipment according to site protocol. Some owners have their operators park the equipment in a circle, with compact equipment placed in the middle to lower the risk of theft.

5. Report Heavy Equipment Theft

According to the National Insurance Crime Bureau, delayed reports of stolen equipment are the No. 1 reason why equipment is not recovered. The quicker you or your operators report the theft, the more likely the equipment will be recovered. If you are a victim of theft, execute these actions:

- Look for it via fleet tracking technologies

- Notify the authorities and relay details of the missing machine, such as size, color and model

- Inform your insurance company to get started on your claim

- Report your machine to the NER

Equipment theft is a frustrating and costly issue in the construction industry. Develop a comprehensive theft prevention plan and promote constant vigilance to help minimize theft and vandalisms.