It’s no secret that fall protection is a vital part of ensuring worker safety. From keeping up with mandatory and consensus safety standards to managing the safety equipment budget, there’s a lot that goes into cultivating a world-class safety program and keeping workers safe—and that includes choosing the right personal protection equipment (PPE) for the application.

This article will discuss an application known as “leading edge.” Specifically, it looks at what the leading edge is and how it relates to one of the most talked-about topics in fall protection—self-retracting lanyards (SRLs). Most importantly, it offers an overview on why leading-edge protection matters and what safety managers need to consider when selecting SRLs for leading edge applications.

What Is Leading Edge?

Without a doubt, construction is a dangerous job. In fact, the Occupational Safety and Health Administration (OSHA) reports that one in five worker deaths were in construction. Further, it notes that falls are the leading cause of death, accounting for 39.2% of total deaths in the industry.

The potential for falls is real. Worse, that potential is complicated by the leading edge. OSHA defines a leading edge as “an unprotected side and edge of a floor, roof, or formwork for a floor or other walking or working surface (such as the deck) which changes location as additional floor, roof, decking, or formwork sections are placed, formed, or constructed.”

Old School vs. New

Traditionally, those working at height have worn a harness attached to an SRL, which was then connected to an overhead anchor point. SRLs acted as a kind of standing safety belt, designed to provide stability, stop a fall, and minimize the force felt by the wearer, should a fall occur. It wasn’t long before some within the industry started using SRLs in a horizontal manner. Soon, the use of horizonal lifelines became common practice within the construction industry and it became known as a leading-edge application.

Swing Fall Hazard

Swing Fall HazardSafety on the Edge

While necessity may be the mother of invention, there’s a major safety problem with attaching an overhead SRL in a horizontal fashion for a leading-edge application: It wasn’t specifically designed for fall events over an edge.

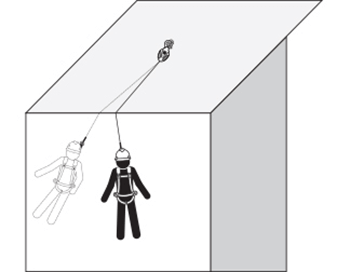

In the event of a fall from a leading edge, a worker using an overhead SRL is at risk of coming in contact with an exposed or sharp edge. That means the lifeline can be frayed, cut, or even severed, putting the worker at great risk of injury incident—or even death. It also means the worker can experience another hazard known as swing fall; a potentially dangerous pendulum-like motion that occurs during and/or after a vertical fall.

Leading Edge Safety: The Solution

Because traditional overhead SRLs have limitations—limitations that can mean the difference between a worker going home safely or not going home at all—it became imperative for the industry, the American National Standards Institute (ANSI), and PPE manufacturers like MSA, to assist in preventing hazards for leading edge applications; namely Leading Edge Self-Retracting Lanyards or SRL-LE.

SRL-LE or leading edge SRLs, allow wearers to tie off at a variety of different anchor points, including: (1) below the back D-ring, (2) at foot level, and (3) overhead. These SRLs have been tested to the leading-edge requirements specified in ANSI Z359.14 2014.

Do You Have the Right Fall Protection for Leading Edge?

Leading edge fall protection has come a long way, thanks to the development of energy absorbers and materials specific to leading edge applications, the protection of edges, and education around anchor points. Because leading edge products can be used in both overhead and foot level tie-off configurations, choosing LE-permitted SRLs can take some of the guesswork out of product selection—especially if you’re unsure if an exposed edge may be a concern at some point during the job.

Here’s are some tips to consider when selecting leading-edge SRLs:

- OSHA 29 CFR 1926.502(k)—Make sure the fall protection plan meets the requirements of this OSHA standard.

- Fall clearance—Foot-level tie-off is the type of anchoring most often used in leading edge applications, so be sure to choose products specifically designed for this and make sure you understand clearance requirements of the product.

- ANSI Z359.14—SRLs that meet these rigorous consensus standards have met the standard requirements for dynamic performance, dynamic strength, static strength, retraction tension, and corrosion protection. (Refer to ANSI Z359.14 for complete requirements details.)

- SRL-LE designation—Only SRLs that pass ANSI’s requirements (Z359.14) for leading edge can include the SRL-LE designation for use in leading edge/sharp edge work so be sure to look for the leading-edge designation on the label.

*Disclaimer: Leading-edge SRLs and all fall protection devices have limitations. Always consider the hierarchy of fall protection when evaluating a project and the safety devices needed.