Believe it or not, nearly 20 years have passed since vehicle manufacturers began introducing telematics systems. Systems like GM’s OnStar and Ford’s Sync are commonplace today on vehicles of all shapes and sizes, and for good reason. Since these systems were introduced, they have provided millions of drivers with roadside assistance, crisis response, navigational assistance and vehicle diagnostics. Considering the extensive investments that contractors, construction businesses, large fleet owners and others make in the heavy equipment they use on jobsites every day, it makes sense that heavy equipment manufacturers have integrated this telematics technology into their machines.

Evolving Technology

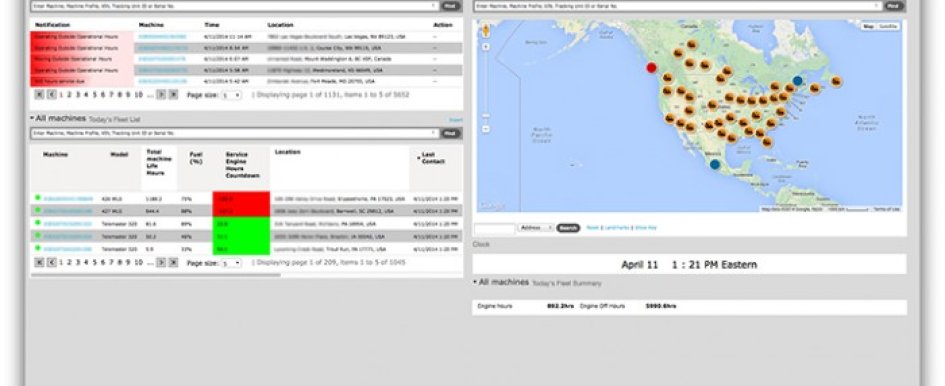

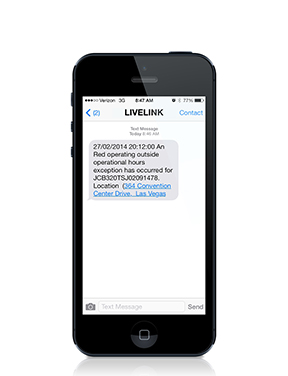

Cellular technology gives telematics systems the ability to provide customers with real-time machine data when the equipment is running. The telematics systems offered by various heavy equipment manufacturers have many similarities, but there are also a few differences. Most telematics systems offer security features like geofencing, machine locating and after-hours alerts. Engine load, duty cycle and fuel economy reporting are also common to most systems. Most manufacturers offer their telematics solutions as a standard on heavy-line equipment, but with varying contract lengths. Far fewer offer features such as a back-up battery and an internal antenna.

Internal antennas are an enhanced security feature because their use means that a potential vandal or thief cannot see visible evidence that a machine is equipped with a telematics solution. Today, like almost any emerging technology, telematics systems continue to evolve with new features like driver-performance reporting and remote immobilization in development. It is unknown exactly how many heavy equipment users currently use telematics systems. However, it is clear that equipment owners and operators are beginning to appreciate this technology that offers so many benefits, especially when used to its full potential.

Dealer Connection

Karli Crockit, JCB’s dealer marketing manager, says that LiveLink and other similar telematics systems also help dealers stay in close contact with customers and their equipment.

“Equipment users don’t typically press a button in their machine to make a call and speak with a specialist,” Crockit explains. However, Crockit said dealers who sell machines can pull up the same machine-specific information that their customers access. This gives dealers the ability to discuss topics like fuel consumption, lost or stolen machines, machine hours and service history with their customers.

“In this way they can build even better long-term relationships with their customers and become trusted advisors,” Crockit said.

Alex MacKinnon, senior vice president of the MacKinnon JCB dealership with locations throughout Florida and south Georgia, says that the primary benefits of telematics systems can be boiled down to three basic things: security, machine uptime and machine management.

“In Florida, honestly, it doesn’t take much for a machine to be quickly spirited away and shipped out of the country,” he says. “These machines certainly aren’t cheap, and that’s why security is a major selling point...”

Keeping a machine up and running is essential to maximizing productivity. Telematics systems can alert customers to major machine maintenance issues or malfunctions, allowing them to take steps to make necessary repairs more quickly. With telematics systems, customers get real-time fault codes that MacKinnon says they can address “when the machine has the human equivalent of a cold—not when it needs open heart surgery.”

“When it comes to machine management, you get to really know what’s going on at the jobsite—not just what your people are telling you,” MacKinnon said. “You get reports of how much your machine is actually being used. This means you can take steps to improve your efficiency and fleet operations.”